Domka ist der exklusive Vertriebs- und Servicepartner der GARBIN und Makbrent GROUP in Deutschland. Mit der Einführung der fernbedienten Grabenfräsen der Serie Garbin Makbrent TZ FIBER OPTIC in den deutschen Baumaschinenmarkt, ist es uns gelungen, eine neue Bauerfahrung für die Glasfaser Projekte vorzustellen. Der Einsatz einer Garbin Makbrent TZ Optic FIBER Grabenfräse wird sowohl die Produktivität der Baustelle mehrfach multiplizieren als auch dem Bauunternehmer mehr Effizienz bieten.

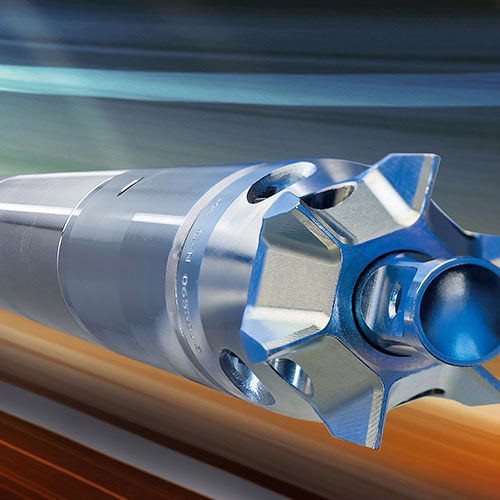

Neben der geläufigen Garbin Makbrent Optic Fiber Mak 630, gibt es die neue Multifunktionsgrabenfräse Multifunctional MF MAK 75. Mit dieser können Sie das Anbaugerät beliebig Dank eines Schnellwechslers verändern und eine Fräskette, Asphaltdeckschicht-Fräse, Betonmischer uvm. verknüpfen.

Die Grabenfräsen TZ Optic Fiber und Multifunctional MAK MF 75 können aufgrund ihrer schmalen Maße und der mächtigen Leistung, auf allen möglichen Flächen eingesetzt werden. Ob es sich um Asphaltoberflächen im Straßenbereich oder um steinigen Boden im Untergrund handelt, sowie Beton, ist kein Hindernis für die Fräse der GARBIN MAKBRENT GROUP geboten. Diese Maschine kann überall flexibel eingesetzt werden.